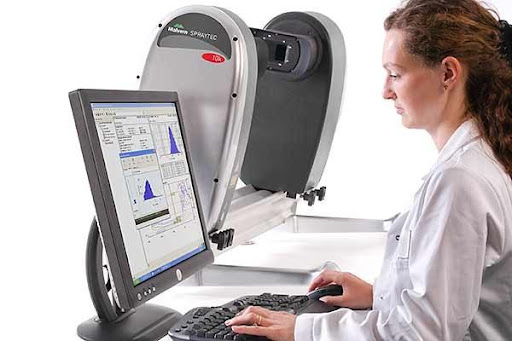

Malvern Panalytical Spraytec

Spray particle and spray droplet size measurement

Inquire about this product:

Malvern Panalytical's Spraytec laser diffraction system allows measurement of spray particle and spray droplet size distributions in real-time for more efficient product development of sprays and aerosols. It has been specifically designed to address the unique requirements for spray characterization and deliver robust, reproducible droplet size data.

Features

Incorporating over 35 years of experience in spray applications, Malvern Panalytical’s Spraytec provides the data required to fully understand spray and atomization processes.

Measurement across a wide size range (0.1 – 2000 microns) without requiring constant optics changes.

Resolve rapid changes in droplet size over time, by measuring up to 10,000 measurements a second.

Deliver accurate, concentration-independent results using a patented multiple scattering analysis.

Characterize wide spray plumes without risking optical contamination.

Simply reveal the dynamic changes in spray particle size through its unique size history analysis software.

System Specifications

Principle: Laser Light Scattering

Analysis: Mie and Fraunhofer scattering including a patented multiple scattering analysis

Data acquisition rate : Rapid mode: 10kHz. Continuous mode: 1Hz

Maximum Measurement Time: Rapid mode: 30 seconds. Continuous mode: 60 minutes

Measurement Triggering: Internal: Based on transmission or light scattering levels. External: Based on TTL input or simple switch trigger

External Device Synchronization: Via 2 TTL trigger outputs

Light source: Max 4mW He-Ne Laser, 632.8nm

Lens arrangement: Fourier (parallel beam)

Lens Focal Length: 300mm and 750mm

Measurement range: 150mm at 0.5 µm, extending to greater than 1m above 5 µm

Detector arrangement: 36 element log-spaced array

Detector angular range: 0.015 – 17 degrees**

Detector alignment: Automatic

Sizing Performance

Particle size: 300mm lens: 0.1 – 900 µm (Dv50: 0.5 – 600 µm). 750mm lens: 2 – 2000 µm (Dv50: 5 – 1600 µm)

Accuracy: Better than 1%***

Repeatability: Better than 1%***

Reproducibility: Better than 1%***

Software: 21 CFR part 11, enables an operating mode that assists with ER/ES compliance

Laser safety: Class 3R, IEC60825-1:2007 and CFR Chapter 1: Sub-chapter J: Part 1040 (CDRH)

Regulatory testing: CE / FCC compliant. Meets requirements of the European Low Voltage directive

Weight and dimensions

Laboratory systems: 950mm optical bench: 950mmx550mmx610mm (36kg). 1400mm optical bench: 37kg 1400x550x610 (37kg)

Spray Facility Systems 950mm optical bench: 950mmx550mmx650mm (36kg). 1400mm optical bench: 1400x550x650 (37kg)

System

Power: 100/240 v, 50/60 Hz

Product storage temperature: -20°C to +50°C

Operating temperature (°C): +15°C to +40°C

Humidity: 80% maximum for temperatures up to 31°C, decreasing linearly to 50% at 40 °C. Non-condensing

Ingress Protection (IP) rating IP65 when in normal use

* This defines the maximum allowable distance between the far edge of the spray plume and the Spraytec receiver lens

** Lens dependent

*** Relates to the measurement of the Dv50 for NIST-traceable latex standards. Sample dependent